Process

Purchase of raw materials

First step of production is to purchase the raw material form our trusted and verified supplier. Material are to be purchased as per the standard material grade or customer's specification

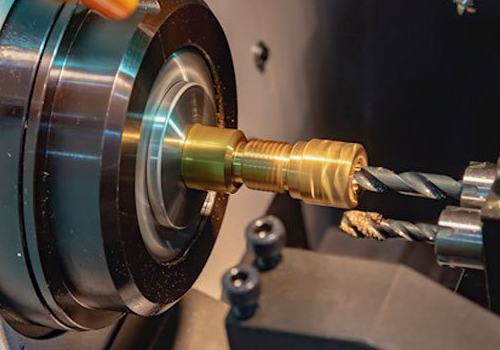

Machining

Here in this step process are likely to be- Threading, Drilling, Facing, milling and cutting. In this process expert engineers are responsible for taking care of measurement, dimensions and quality checking of products.

The company has all the essential tools and machines to manufacture quality products. We guided our staff to assure the perfection in every product. Thus qualified and trained staff manufactures our products.

Buffing Polishing & Platting

For manufacturing products, we use Copper, Gun Metal, Bronze, S. S., Brass, Aluminum material. For plating the products we use, Electro Tin Plating, Electro Nickel Plating, Electro Copper Plating, Gold Plating, Electro Silver Plating, and Blasting. Also, we can manufacture all our products as per customer requirements and specifications.

Quality Checking & Testing

We are always focusing on the quality of the products. So that, the products are checked during production and packing. All products manufactured are tested and verified for 100% quality. For testing the quality of the products we are available with various testing Equipment such as Veriner caliper, spectro are used for appropriate size and measurement for final products.

Packaging & Customer feedback

We take proper care while packing the products. We deliver products in PVC Bag, Thermal PVC Tray for a small part, Plain Box, Shrink Wrapping, Auto Strapping Machine, Wooden Cases, and Wooden Pallets to avoid the damage in the products.